|

|

|

|

|

|

|

|

Click any photo for larger image.

The Move to Hydraulics

|

|

|

By the mid nineteen fifties, although Coles were one of the largest manufacturers of cranes in the world, they were seeing competition rising from not only smaller firms, who were innovating with more modern systems, but also from Europe where large firms were establishing themselves with both mechanical drives and hydraulics.

Coles electrical systems were getting a new era was coming, Coles needed to develop new ranges of mechanical and hydraulics cranes.

By the mid nineteen fifties, although Coles were one of the largest manufacturers of cranes in the world, they were seeing competition rising from not only smaller firms, who were innovating with more modern systems, but also from Europe where large firms were establishing themselves with both mechanical drives and hydraulics.

Coles electrical systems were getting a new era was coming, Coles needed to develop new ranges of mechanical and hydraulics cranes.

|

Hydraulic Cranes were nothing new, the water hydraulic crane had been made in the late 1800s, but they were of limited use. This rail mounted hydraulic crane was offered in Cole catalogue in 1879 and seems to be the only rail mounted hydraulic crane ever offered for sale. Weather if was ever built is another matter, they did build static ones as did other manufacturers. Hydraulic Cranes were nothing new, the water hydraulic crane had been made in the late 1800s, but they were of limited use. This rail mounted hydraulic crane was offered in Cole catalogue in 1879 and seems to be the only rail mounted hydraulic crane ever offered for sale. Weather if was ever built is another matter, they did build static ones as did other manufacturers.

|

|

|

|

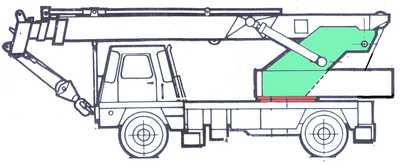

It was not until oil hydraulics had been perfected was it possible to utilise it for something as critical as crane lifting. Coles was looking of way of improving the strut jib system, where a crane was always followed by lorries carrying its jib components. They experimented with mechanically extending jibs (left ) before settling on trying to load all the jib sections onto the basic crane.

It was not until oil hydraulics had been perfected was it possible to utilise it for something as critical as crane lifting. Coles was looking of way of improving the strut jib system, where a crane was always followed by lorries carrying its jib components. They experimented with mechanically extending jibs (left ) before settling on trying to load all the jib sections onto the basic crane.

These were known, not surprisingly as "Jib Carriers" An example of this is the Leda (top image - upper right). This system however was developed at the same time as the first hydraulics cranes were being developed, so was short lived.

|

Coles made a move in 1959 to consolidate the British market and merged with two firms with experience in different aspects of the crane market. The first of these was N.H.Neal and Son of Grantham, who were producing heavy diesel mechanical and diesel hydraulic cranes, at this time they were third largest manufacturer of cranes in the country. The second firm was a much smaller operation altogether, F. Taylor & Son of Glazebury. This firm, who only had three small cranes on the books, specialised in mining machinery. They had been developing hydraulic drives and had a good ten years of experience in this area. Probably, and most importantly for Coles, they held the patent for an important invention, the Hydraulic Rotary Coupling.

Coles made a move in 1959 to consolidate the British market and merged with two firms with experience in different aspects of the crane market. The first of these was N.H.Neal and Son of Grantham, who were producing heavy diesel mechanical and diesel hydraulic cranes, at this time they were third largest manufacturer of cranes in the country. The second firm was a much smaller operation altogether, F. Taylor & Son of Glazebury. This firm, who only had three small cranes on the books, specialised in mining machinery. They had been developing hydraulic drives and had a good ten years of experience in this area. Probably, and most importantly for Coles, they held the patent for an important invention, the Hydraulic Rotary Coupling.

|

When Coles took over these firms in 1959 the chief designer at the time, Bob Lester, saw that hydraulics were to be the future.

When Coles took over these firms in 1959 the chief designer at the time, Bob Lester, saw that hydraulics were to be the future.

At this time N H Neal's were making a heavy lift hydraulic crane the 'HyMax'which could lift 4.5 tons. This machine (image left ) was a low headroom industrial works crane.

|

Neals 'HyMax'

|

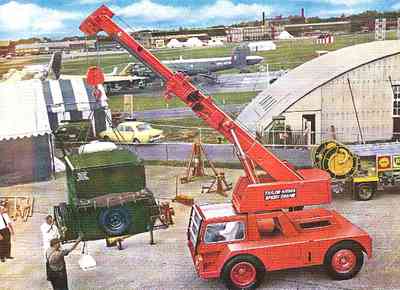

Taylor's had three small hydraulic machines developed mostly for mining opperations. (below) All these cranes were selling quite well and formed the basis for Coles to move into hydraulics.

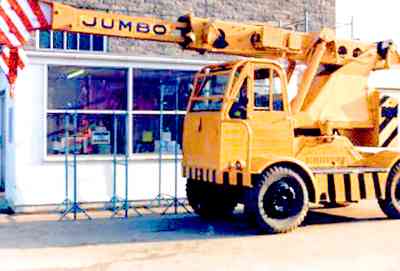

These machines were, firstly the Jumbo 4x2 a small light industrial crane. Second The series 50, a 4x2 light road legal light fast travel unit and lastly The Series 42, a 4x4 rough terrain unit popular with the army and civil engineers. Form these units Bob Lester and his team from Coles were to develop three complete ranges of hydraulic crane.

|

|

|

1962 SPEEDCRANE

The first action was to give the small Jumbo a makeover, this was mostly cosmetic except for the cab which they pulled the forward allowing access from the side rather than the front. They made all the wheels the same size, decked over the chassis so covering all the wheels for safety and placed side guards on the rotating part of the jib turret. This was then marketed in 1962 under the Coles banner as the Coles 4 ton Speedcrane. The first action was to give the small Jumbo a makeover, this was mostly cosmetic except for the cab which they pulled the forward allowing access from the side rather than the front. They made all the wheels the same size, decked over the chassis so covering all the wheels for safety and placed side guards on the rotating part of the jib turret. This was then marketed in 1962 under the Coles banner as the Coles 4 ton Speedcrane.

|

1962 Speedcrane 1962 Speedcrane |

1959 Series 50 1959 Series 50 |

1966 HYDRA TRUCK

In the early sixties hydraulics had been applied to a range of jib carriers with limited success it was clear that the hydraulic multiple shaft boom was the way forward.

In the early sixties hydraulics had been applied to a range of jib carriers with limited success it was clear that the hydraulic multiple shaft boom was the way forward.

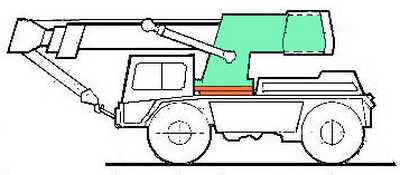

Taking the basic superstructure from the series 50 unit and developing a heavier boom, Coles design team then placed this unit on an existing Sunderland designed chassis. As this was a marriage between two existing designs the cab of the lorry had to be lowered to give the boom clearance over it. |

This machine the 101 was first launched at the 1966 Mechanical Handling Exhibition under the name Hydra Truck 10 T where proved a great success and over two hundred were ordered. (Hydra was a Taylor's trade name)

This machine the 101 was first launched at the 1966 Mechanical Handling Exhibition under the name Hydra Truck 10 T where proved a great success and over two hundred were ordered. (Hydra was a Taylor's trade name)

|

1966 Hydra 10 ton 1966 Hydra 10 ton |

Detail of the jib frame Detail of the jib frame |

The 101 machine was essentially a prototype and although a number of theses were made the design needed to be updated. The drooped cab was not practical and the superstructure was not strong enough. A new design was required. The 101 machine was essentially a prototype and although a number of theses were made the design needed to be updated. The drooped cab was not practical and the superstructure was not strong enough. A new design was required.

|

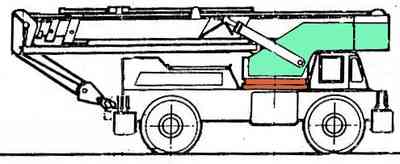

The boom support was simplified by designing a simple double plate system. Two heavy steel plates were made to sit each side of the boom and angled with the toe taking the boom pivot pin.

The boom support was simplified by designing a simple double plate system. Two heavy steel plates were made to sit each side of the boom and angled with the toe taking the boom pivot pin.

|

|

The boom support was simplified by designing a simple double plate system. Two heavy steel plates were made to sit each side of the boom and angled with the toe taking the boom pivot pin. The bottom of these plates were fixed to the top of the 'Slew Ring', the legs of the support plates could be high enough to rase the jib over a higher cab which meant the cab unit could be mounted on top chassis. These two plates would not only provided space for the larger boom, but provide anchor points for the hydraulic rams and provide space between for the rotary coupling and slew motor. The counterweight and winding drum was held low, reducing the centre of gravity, just above the slew ring by two channel sections on the outside of the plates.

The boom support was simplified by designing a simple double plate system. Two heavy steel plates were made to sit each side of the boom and angled with the toe taking the boom pivot pin. The bottom of these plates were fixed to the top of the 'Slew Ring', the legs of the support plates could be high enough to rase the jib over a higher cab which meant the cab unit could be mounted on top chassis. These two plates would not only provided space for the larger boom, but provide anchor points for the hydraulic rams and provide space between for the rotary coupling and slew motor. The counterweight and winding drum was held low, reducing the centre of gravity, just above the slew ring by two channel sections on the outside of the plates.

|

Details of the redesigned telescopic boom support.

Details of the redesigned telescopic boom support.

|

Taylor's factory at Glastonbury were not big enough to cope with the heavy engineering required so the new machine was made in the main Sunderland factory.

This new update of the Hydra 10 ton machine the 102 was introduced in 1967 less than year after the first Hydra.

Taylor's factory at Glastonbury were not big enough to cope with the heavy engineering required so the new machine was made in the main Sunderland factory.

This new update of the Hydra 10 ton machine the 102 was introduced in 1967 less than year after the first Hydra. |

|

1967 HYDRA HUSKY 1967 HYDRA HUSKY

While the design team was working on the Hydra truck they also turned their attention to the of the rough terrain unit, a crane basically for site civil engineering and construction work where there were no roads, this was what the Taylor's series 43 unit was used for. The Taylor's unit was a light lift however and the construction industry wanted something with a much bigger lift. The Taylor unit basically used old ex-army four wheel drive trucks as a base for putting their hydraulic unit on. While the design team was working on the Hydra truck they also turned their attention to the of the rough terrain unit, a crane basically for site civil engineering and construction work where there were no roads, this was what the Taylor's series 43 unit was used for. The Taylor's unit was a light lift however and the construction industry wanted something with a much bigger lift. The Taylor unit basically used old ex-army four wheel drive trucks as a base for putting their hydraulic unit on.

|

A new chassis was designed, a simple H frame built from steel sections and using the diesel mechanical drive systems with four wheel drive and four wheel steering. These were strong units with large wheels and high ground clearance.

A new chassis was designed, a simple H frame built from steel sections and using the diesel mechanical drive systems with four wheel drive and four wheel steering. These were strong units with large wheels and high ground clearance.

The slewing unit of crane needed to be bigger and stronger than the light one used on the ten ton lorry. Unlike the Lorry unit the RT unit would be a lift and carry machine lifting mostly from a position in front of the drivers cab.

|

The L plate support developed The L plate support developed

for the Husky |

|

The design was solved by modifying the design used on the lorry unit a simple 'L' plate system. Two heavy steel inverted 'L' plates were made with the top leg of the 'L' sitting on the 'Slew Ring', the long leg of the L would rase the jib support above the cab of the unit. These plates provided space a larger boom, provide anchor points for the hydraulic rams, space for the rotary coupling, slew motor and counterweight. The high counterweight was possible because of the extra weight of the chassis, this configuration also allowed for a shorter wheel base.

The design was solved by modifying the design used on the lorry unit a simple 'L' plate system. Two heavy steel inverted 'L' plates were made with the top leg of the 'L' sitting on the 'Slew Ring', the long leg of the L would rase the jib support above the cab of the unit. These plates provided space a larger boom, provide anchor points for the hydraulic rams, space for the rotary coupling, slew motor and counterweight. The high counterweight was possible because of the extra weight of the chassis, this configuration also allowed for a shorter wheel base.

|

1967 First Coles Husky

|

By 1967 the first Hydra Husky 150 15 ton unit was put on the market.

It was an immediate success and demand meant production, initially at the Sunderland plant, was moved to the Neals Grantham works, where eventually the whole range of Husky's were to be built.

|

1968 SPEEDCRANE 1968 SPEEDCRANE

After the Husky the design team came back to the Speedcrane. Using all the design elements developed with the other units the Speedcrane was to be come a road legal mini Husky. A strong chassis with the slew ring bolted directly to with the Husky 'L' frame boom support replacing the weak tower of the old unit. After the Husky the design team came back to the Speedcrane. Using all the design elements developed with the other units the Speedcrane was to be come a road legal mini Husky. A strong chassis with the slew ring bolted directly to with the Husky 'L' frame boom support replacing the weak tower of the old unit.

|

L plate Speedcrane boom support L plate Speedcrane boom support |

With rear wheel steering, single position driver operation and ease of deployment made this a very popular crane.

This re-designed small crane was given to the upgraded Taylor's factory at Glastonbury for full production.

|

The redesigned unit was put on the market in 1968 as the Coles Speedcrane 5 ton unit.

In the following years the Speedcrane was gradually upgraded to eventually become a 12 ton lift, yet this small unit was to retain it basic configuration almost unchanged for the next twenty years.

|

|

Coles were now set to develop these reanges onto three quite separate groups of hydraulic crane.These would eventually replace all their other mobile jib cranes. Coles were now set to develop these reanges onto three quite separate groups of hydraulic crane.These would eventually replace all their other mobile jib cranes.

To see full details of all the hydraulic cranes see the Hydra, Speedcrane and Husky sections of the main database

|

|

| |