|

|

||||||||||

|

Click on any picture for bigger image

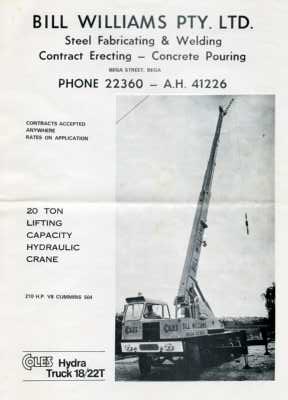

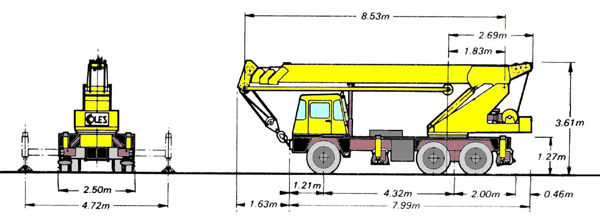

Coles Hydra 18/22 |

||||

|

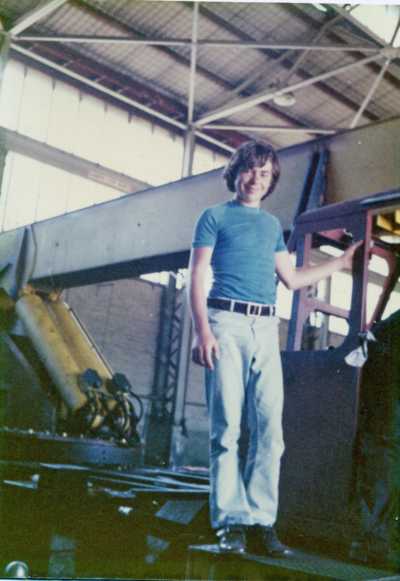

The information and photographs were given to me by the son of the owner Mark Williams to whom I express my thanks for this information. The story below is in Marks own words, the teenager in the photo No 10 is Mark.

|

||||

|

|

||||

1. 1.

2. 2.

3. 3.

|

||||

|

|

||||

|

It had out riggers that came out and down. This was and option at the time. The unit had a choice of two makes of motors the ACE and the Cummins. Two Cummins Motors were the V8 504 Diesel and the 903 V8.

My father choose the Cummins 504 V8 motor at the time as the hydraulic power take off required this.

In the hilly areas of country New South Wales where we lived the machine was very under powered for road used. The maximum speed was about 42 Miles per hour.

At speed the machine would bounce because of the single front axle. The weight on the back chassis of the crane causing this. This was later corrected by adding the extra front axle.

At high speed the brakes were not as effective as they should have been so we fitted JOBS engines braking system to the machine.

The Coles that we chose came standard with twin Eaton bogy drive rear differentials, a 13 Speed Road Ranger gear box and the 504 Cummins Motor.

The Australia built versions were rated at there normal rates but by law here and because the Hydraulic crane principle was new at the time, they had to have 22 % over load factor. So if a crane was rates at 22 Metric Tons its actual rating was 26.95 Metric Tons. Later this was increased to 33 % and then dropped several months after that as the cranes were a proven unit by then.

I can remember my father going off at the General Manager of Coles Cranes here in Australia and this was about six months after we had purchased the crane. This was because the welds on the slewing ring cover plate and the uprights that hold the rams started to crack.

All I Know is that, Coles repaired it on site in the country. They fitted from memory six gussets on each side and this was done to all future cranes they manufactured. They said that this was caused by the side ways movement of the load when slewing. We never had any more problems with this machine apart from the ring gear on the engine having to be replaced because of and electrical design fault.

The jib was the only part fabricated at the parent companies factory in England and imported into Australia, as there were no plasma profiling machines in Australia at that time, to cut the jib panel plates flat and straight in water. Later these were made in Australia.

Coles cranes factory in Australia closed down in the late seventies as part of the reorganisation under Acro. There also pressure from the Japanese Koko cranes in this part of the world were they were much cheaper machines.

Cranes took 16 weeks to make from the time the order was signed to delivery. Actual fabrication time and testing was 6 weeks.

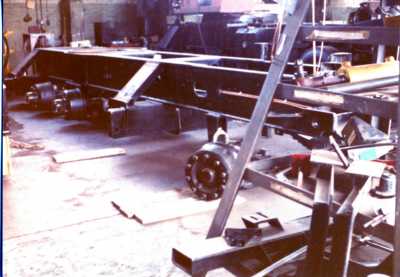

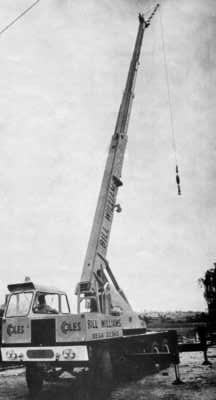

Image 11 Crane being checked after driving off the assembly line for load and road testing Image 1 Top of page is the Crane several days after delivery. |

||||

|

The Road Range 13 speed gear box chosen for this machine was bigger in height than the AEC gear boxes normally used.

The Cummins and the Road Range gear box gave the 1 to 1 for the Oil Pumps in RPM from the motor. We chose the Cummins and the Road Range because of this and being the countryside the 13 speed gear box would be better suited to the extremely high hills and mountains of the area. i.e. Bellbird hill, Mc Clouds hill, Doctor George Mountain etc. You have to be able to go up and down these to get on the plains behind the coast.

These cranes were the only cranes at the time that could legally pick and carry a load with the boom over the back end. Secondly they had the option of being fitted with a computer control pack. What the control pack did was, if the crane was in trouble and being overloaded the crane would stop and return to the last known safe working load position. This was fitted much later to our crane, this was because the extremerly high price of computer units in those days. |

||||

12.

12. | ||||

|

Two views of the crane doing whart it was ment to do. Errecting Steel at Pambula Beach industrial Area, Merimbula in Southern New south Wales.  13. 13.

14. 14. | ||||

|

|

||||

Thanks - Mark Williams story and photos |

||||

|

|

||||||||||