|

|

||||||||||

|

Coles Hydra 18/22 Specification Sheet |

||||

|

||||

|

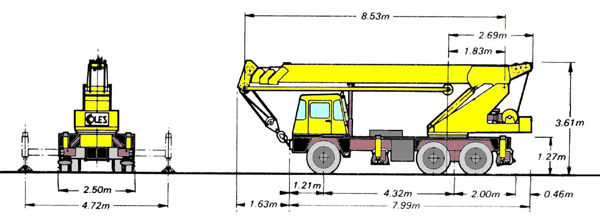

GENERAL DATA Maximum Negotiable Gradient— 1 in 2 (36.5%). Turning Radius — 35'0"(10.67m) kerb to kerb. Approximate Weight —54275 lb (24620 kg).

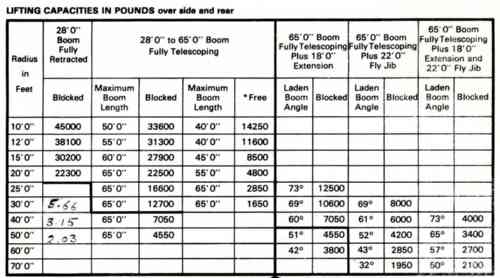

OPERATING SPEEDS AND CAPACITIES Hoisting — see table on page 5. Boom Telescoping — 53 ft mm (16.2 rn/mm ) Traveling — 37.5 miles h (60 km h)

CRANE DATA Hydraulic Pumps — dual type hydraulic pump of 35 7 imperial galls. per mm. (162 litres per min and 28 imperial galls. per mm (127 litres per mm) capacity at maximum engine speed. Driven by propeller shaft from gearbox power takeoff.

Hydraulic Control Valves — are provided for control of hoist, slew, derrick and boom telescoping and for independent operation of the hydraulic outriggers. Control valves are normally operated from the drivers cab. To assist the driver in jib erection the operating levers are duplicated at the rear of the chassis If required, outrigger control levers can be duplicated on the chassis sides.

Derricking Rams double acting twin rams with chrome plated piston rods and honed bores A counterbalance valve is fined to provide positively controlled derricking-out.

Telescopic Boom Ram — double acting ram of 18'-6"(5.64m) stroke housed within the boom A counterbalance valve is fitted to provide positively controlled boom retraction.

Slew Gear - gear type motor driving the slewing pinion through a worm reduction gearbox A torque limiting clutch is incorporated in the pinion shaft to protect the mechanism, and a hydraulically released spring applied fail safe type brake is fitted to jib worm shaft.

Hoist Gear - gear type motor driving the grooved hoist drum through a double reduction spiral bevel and planetary gearbox. A hydraulically released spring applied fail safe brake is fitted to the Input shaft and a counterbalance valve is fitted to provide controlled lowering of the load.

Slew Ring - double row hall bearing slew ring with integral teeth meshing with the slew Unit pinion.

Boom - fabricated from high tensile alloy steel, with pivot points bushed for long life The telescopic portions of the boom slide on adjustable pads faced with special wear-resistant fiber bearings

Extension Section - a 18'-0" (5.49m) boom extension is housed within the inner boom Facilities are provided for power repositioning of the extension.

Safety Devices - Hydraulic overload valves, sealed against unauthorised interference, automatically protect the pump and crane Structure from damage in the event of excessive pressure A hoist limit switch operating an engine cutout prevents over-hoisting and over lowering. Positive lock valves are fitted to the derricking, telescoping and outrigger rams to prevent sup, even in the event of hose failure

|

||||

Thanks - Richard Blokker for the above information. |

||||

|

|

||||||||||