|

|

||||||||||

|

Coles Hydra 6x4 12 Ton - Specification Sheet |

||||

|

||||

|

GENERAL

The Coles Hydra 1 50T is a self-propelled, diesel-hydraulic one-man operated, fully slewing mobile crane on a specially designed crane carrier chassis fitted with hydraulic outriggers.

The travel motion is driven direct by the diesel engine via a multi speed gearbox and normal automotive controls are provided. A power take-of on the gearbox drives the tandem hydraulic pumps that power the rams and motors of the various crane motions. The upholstered driver's seat is reversible so that for crane operation the driver faces the superstructure and crane controls.

Numerous advanced safety devices include automatic disc brakes to hoist and slew motions, dual-line air braking system to road wheels, limiting cut-out to prevent over-hoisting and over-lowering, positive lock valves on all rams, hydraulic overload by-pass valves and low pressure remote control counterbalance valves.

Outstanding features are the telescopic boom actuated by a large diameter hydraulic ram and lacing chain providing automatic synchronisation of telescoping sections, three speed hoist providing infinite speed variation. and independent or simultaneous operation of crane motions.

GENERAL DATA

Maximum Negotiable Gradient - 1 in 3 (33%) Turning Radius - "35' O'' ( 10 67 m) kerb to kerb. Approximate Weight - 24 05 tons (24430 kg). Hydraulic Oil Tank Capacity - 90 gallons (409 lt) Fuel Tank Capacity - 40 gallons (181 It). OPERATING SPEEDS AND CAPACITIES Hoisting - 2 tons (2000 kg) at 200 r.p.m. (61 m.p.m) Derricking maximum to minimum radius in 22 seconds. Minimum to maximum radius in 12-20 seconds. Slewing - 2 r.p.m. unladen Boom Telescoping - 80 f.p.m. (24 4 m.p.m). Boom Capacities - Loads up to 6 tons (6000 kg) can be fully telescoped. Loads from 6 tons (6000 kg) to 10 tons (10000 kg) can be partially telescoped. Travelling - 33 m.p.h. (53 k.p.h.) .

CRANE DATA Hydraulic Pumps - dual type hydraulic pump of 45 galls per min. (,204 fir. per min.) and 22 galls per min. (99 lt. per min.) capacity al 2000 r.p.m. Driven by propeller shaft from gearbox power take-off. An oil cooler is incorporated in the hydraulic system.

Hydraulic Control Valves - two control valves - a three plunger type and two plunger type are provided for control of hoist, slew derrick and boom telescoping. A further four-plunger valve section is provided for independent operation of the hydraulic outriggers. Control valves are normally operated from the driver's cab. To enable the driver to control the crane from an alternative vantage point, the operating levers are duplicated at the rear of the chassis. If required, outrigger control levers can be duplicated on the chassis sides.

Derricking Rams - double acting twin rams with chrome plated piston rods and honed bores, mounted on spherical bearings. A counter balance valve is fitted to provide positively controlled derricking out.

Telescopic Boom Ram - double acting ram of 17 O ' (5 18 m) stroke housed within the boom. A counterbalance valve is fitted to provide positively controlled boom retraction.

Slew Motor - gear type motor driving the slowing pinion through a worm reduction gearbox. A torque limiting clutch is incorporated in the pinion shaft to protect the mechanism and a hydraulically released spring applied fail safe type disc brake is fitted so the worm shaft.

Hoist Motor - gear type motor driving the grooved hoist drum through a worm reduction gearbox. A hydraulically released spring applied fail safe brake is fitted to the worm shaft and a counterbalance valve is fitted to provide controlled lowering of the load.

Slew Ring - double row ball bearing slew ring with integral teeth meshing with the slew unit pinion.

Boom - fabricated from high tensile alloy steel, with pivot points bushed for long life. The telescopic portions of the boom slide on self-aligning pads faced with special wear-resistant fibre bearings.

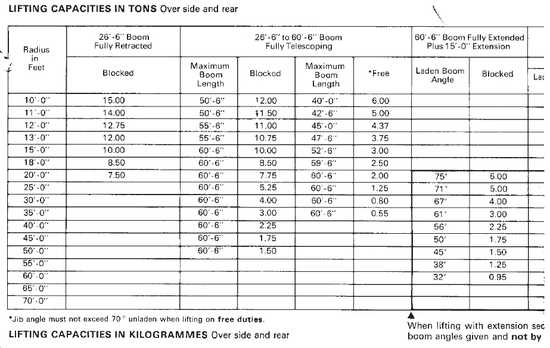

Extension Section - a 15'0'' (4 57 m) boom extension is housed within the inner boom. Facilities are provided for power repositioning of the extension.

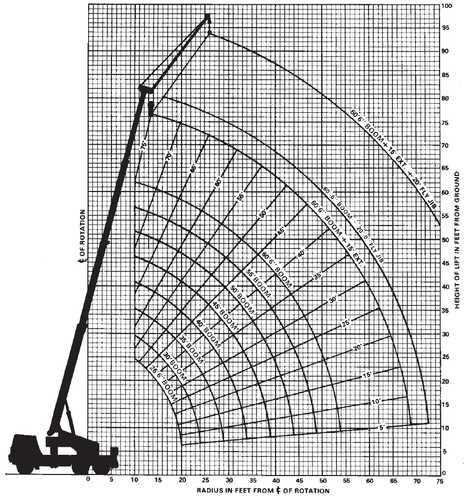

Safety Devices - electronic fully automatic safe load indicator, calibrated for 2B'6' (8 10 m), 60'6'' (18 40 m) and 75'6" (23 00 m} boom length warns the operator both visually and audibly of any tendency to overload the crane. Hydraulic overload valves, sealed against unauthorised interference, automatically protect the pump and crane structure from damage in the event of excessive pressure. A hoist limit switch operating an engine cut-out prevents over-hoisting and over-lowering. Positive lock valves are fitted to the derricking, telescoping and outrigger rams to prevent slip, even in the event of hose failure.

CHASSIS DATA

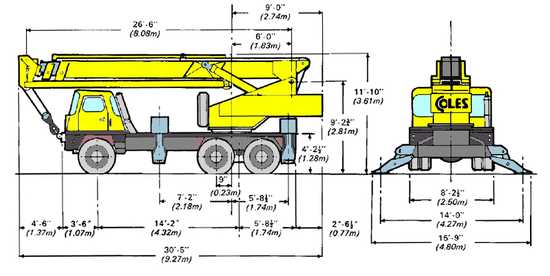

General - 6 x 4 wheel drive chassis specially designed for crane service. The frame is fabricated from heavy rolled steel sections and plates and houses four hydraulically operated power outriggers.

Engine - A.E.C. AV505, 6-cylinder, 8 2 litre, water cooled diesels developing 158 b.h.p. at 2200 r.p.m. Maximum torque, 391 lb. ft. (5407 kgm.) at 1400 r.p.m. An engine hour meter is fitted.

Gearbox - providing five forward speeds and one reverse with integral two-speed auxiliary gearbox.

Rear Bogie - tandem axles with rocking beam suspension. Reduction by worm and wheel 8 25:1 ratio with bevel gear differential and inter- axle differential with lock.

Steering Axle - alloy steel beam mounted on leaf springs and fitted with heavy duty stub axles.

Brakes -full air pressure dual-line brakes acting on all wheels. Spring actuators for emergency and parking use operate on the rear wheels.

Tyre Equipment - 11 00 x 20 pneumatics. Twins fitted on rear bonier singles fitted on front axle, on pressed steel ventilated wheel discs. A power operated tyre pump is provided and a spare wheel is carried on the superstructure.

Steering - cam and double roller type, with hydraulic power assistance.

Driver's Cab - totally enclosed, full width cab with three windscreen wipers, front windscreen washers, adjustable reversible driver's seat, and mate's seat. Travel controls arranged at the front of the cab and crane controls at the rear.

Electrical Equipment - 24 volt, full road lighting including flashing direction indicators.

OPTIONAL EQUIPMENT

Left hand drive chassis in lieu of right hand drive.

Cab heater - in chassis cab.

Single hook and pearweight.

Tropical cab - with fan and opening window.

Fly jib - one piece 20'0'' (6.10 m) centres.

Special Painting.

Duplicate outrigger controls - at sides of chassis.

Two-fall lightweight hook block.

Operator's cab - mounted on slewing superstructure, totally enclosed with adjustable operator's seat, windscreen wiper and full crane controls. The crane controls mounted in the driver's cab and at rear of chassis on standard crane are omitted, and the hydraulic outrigger controls are repositioned at sides of chassis.

Windscreen Wiper - to roof window of drivers cab, or operator's cab when fitted.

|

||||

Thanks - Brian Reynolds (cranepart ltd) |

||||

|

|

||||||||||